Gypsum quarrying began in Nova Scotia in the 1770s, when farmers in Hants County first found gypsum deposits (or plaster as they called it) on their land and started exporting to the United States. By 1818 the industry employed over 150 men locally and 50,000 tons were being shipped annually, mostly for use as fertilizer.

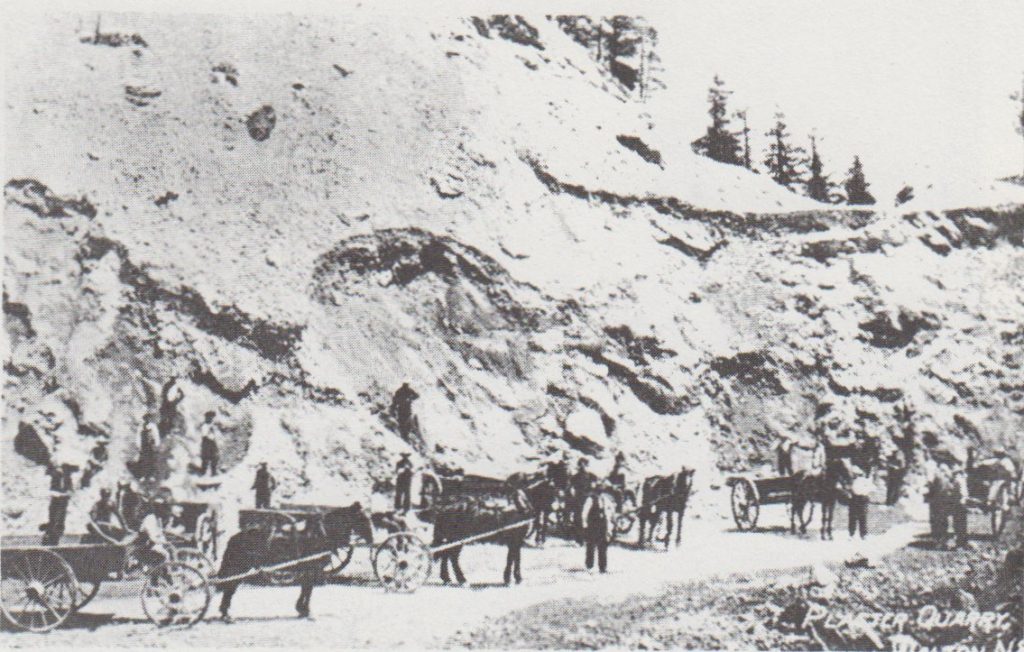

Many small quarries with names such as Mudbank, Cables, Weatherspoon, Eagle Swamp, Fraser, Meadow, and Blue Rocks operated in the Avondale and Wentworth area.

Most of the Gypsum Company land holdings at Wentworth were put together by Richard Cunningham between 1800 and 1830 and by his son, Perez Morton Cunningham, between 1854-1860. The Cunninghams generally had little operating capital and leased their quarries for yearly time periods to many different people. In 1867 Samuel Sweet bought 1175 acres from the Cunningham estate. He made various deals with E.W. Dimock later selling 1379 acres of land, buildings, gypsum and wharfs for $13,000.

Dimock operated the quarries and shipped rock until 1881 when he sold half of the land at Wentworth to J.B. King from New Brighton, New York, for $30,000. The Wentworth Gypsum Company was incorporated in 1891. The major players were Edward Dimock, his sons Clarence and Norman, J.B. King and George H. Wooster.

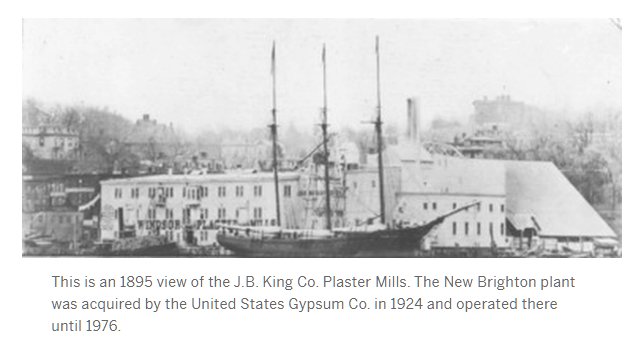

Jose Berre (J.B.) King (1854-1913) made a fortune shipping raw gypsum rock to New York, reloading his schooners with American products and returning to Nova Scotia on the same ships. As far back as 1891 he had been associated with the quarry at Wentworth, in Hants County, Nova Scotia. His plant at New Brighton on Staten Island in New York harbour was called the Windsor Plaster Mill.

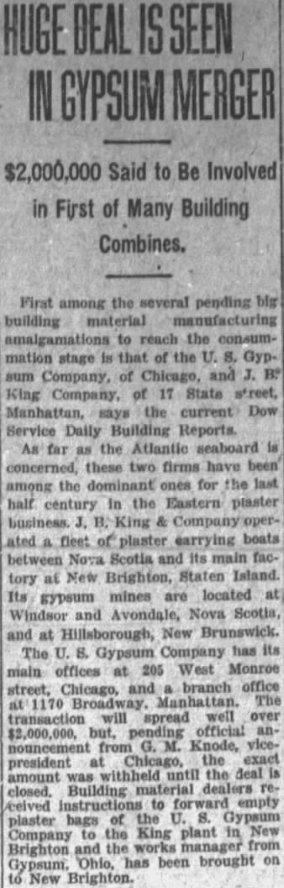

J.B. King and Company eventually gained control of the Wentworth Gypsum Company and on January 1, 1924 the Canadian Gypsum Company, a subsidiary of the United States Gypsum Company, bought the Wentworth Gypsum Company Limited.

Property acquired included lands and gypsum, quarrying equipment, railroads, a loading dock at Avondale, small-dock property at Hantsport, and a crushing plant, storage shed and loading dock and equipment at Wentworth. This latter equipment was capable of handling ocean going vessels for approximately eight months of each year before becoming ice-bound.

Immediately upon acquisition of the property, the Canadian Gypsum Company provided new stripping equipment, air compressors, drilling equipment and shovels for loading the rock. The capacities of the crushing plant and storage and loading facilities at Wentworth were also increased.

For almost a quarter of a century, J.B. King would have nothing to do with Sewell Avery, president of US Gypsum. But Avery was patient, and King was mortal. So after King died his New Brighton, N.Y., plant on Staten Island became part of United States Gypsum Company; his quarry operations in Nova Scotia, part of Canadian Gypsum Company; and his ships, part of the Panama Gypsum Company. “No amount of hyperbole can overstate the importance of this acquisition to the long-term success of U.S. Gypsum.”

|  (Brooklyn, New York) · 7 Jan 1924 |

Shipping

The shipping site for Fundy Gypsum Company Limited and preceding companies has changed during the years.

Prior to 1895 there were more than six wharfs on the St. Croix River handling gypsum and more than that on the Avon River. After the Gypsum Packet Company was formed in 1891 by E.W. Dimock and Sons and J.B. King, who was succeeded by his brothers George R. and Jerome A. King, the Wentworth Gypsum Company and later companies shipped the gypsum from the wharf behind Fundy Gypsum’s main office at Wentworth. This remained in service until 1947 when the company ships increased in size from 7000 to 11,700 tons and became too large to handle in the St. Croix River.

The company started shipping with small sailing vessels of 600-700 tons. As the age of sail was ending, larger ships of 1000-2000 tons were bought and converted to barges. The self-powered ships started hauling cargo around 1920. Ships that went to the Wentworth wharf were escorted by a tug boat, i.e. the 36-ton Chester, built in 1890, the Mumford and the wooden Otis Wack I. The barges of 1901-1924 were hauled to the New York area by the ocean-going tug, L.B. King.

Wooden Sailing Ships

| NAME | TONS | YEAR BUILT | YEAR CONVERTED | END OF SERVICE |

| Gypsum Queen | 652 | 1891 | – | Sank 1915 (Topedoed) |

| Gypsum King | 676 | 1892 | – | Sank 1906 |

| Gypsum Princess | 664 | 1892 | Sank 1898 | |

| Gypsum Emperor | 694 | 1892 | – | Sank 1913 |

| Gypsum Prince | 723 | 1892 | – | Sank 1895 |

| Gypsum Empress | 723 | 1892 | – | Sank 1917 |

Wooden Sailing Ships Converted to Barges

| NAME | TONS | YEAR BUILT | YEAR CONVERTED | END OF SERVICE |

| Ontario | 825 | 1876 | 1901 | Beached 1921 |

| Lizzie Burril | 1185 | 1875 | 1902 | Sank |

| Bristol | 1305 | 1878 | 1903 | Sank 1921 |

| Whitney | 1895 | 1905 | ||

| Plymouth | 1312 | 1879 | 1906 | Beached 1920 |

| Wildwood | 1579 | 1883 | 1907 | Beached 1920 |

| Hamburg | 1743 | 1886 | 1908 | Beached 1920 |

| Canada | 2137 | 1891 | 1909 | 1923 Dismantled 1926 |

| Glooscap | 1734 | 1891 | 1910 | Sank 1924 |

| Kings County | 2225 | 1890 | 1912 | Dismantled 1926 |

Diesel and Sail (Wooden)

| NAME | TONS | YEAR BUILT | YEAR BOUGHT | END OF SERVICE |

| Munro | ? | ? | ? | Beached 1939 Refitted 1942; Later Sank |

Steam (Wooden)

| NAME | TONS | YEAR BUILT | YEAR BOUGHT | END OF SERVICE |

| Gypsum King | 4300 | From U.S. Government | 1920 | ? |

| Gypsum Queen | 4300 | From U.S. Government | 1920 | ? |

Steam (Steel)

| NAME | TONS | YEAR BUILT | YEAR BOUGHT | END OF SERVICE |

| Gypsum King | 5000 | 1927 | 1927 | In British Service 1941-Nov. 1945 |

| Gypsum Princess | 5000 | 1927 | 1927 | Lost in WWII after 1941 |

| Gypsum Prince | 5000 | 1928 | 1928 | Lost in WWII after 1941 |

| Gypsum Queen | 5000 | 1928 | 1928 | Lost in WWII after 1941 |

| Gypsum Empress | 5000 | 1928 | 1928 | Lost in WWII after 1941 |

Steam (Steel)

| NAME | TONS | YEAR BUILT | YEAR BOUGHT | END OF SERVICE |

| Gypsum Prince | 11700 | 1947 | 1947 | 1976 |

| Gypsum Queen | 11700 | 1947 | 1947 | 1975 |

| Gypsum Dutchess | 11700 | 1956 | 1956 | 1986 |

| Gypsum Countess | 11700 | 1961 | 1961 | 1989 |

| Gypsum Empress | 11700 | 1955 | 1955 | 1983 |

| Gypsum King | 19200 | 1975 | 1975 | |

| Gypsum Baron | 19200 | 1976 | 1976 |

Diesel (Steel)

| NAME | TONS | YEAR BUILT | YEAR BOUGHT | END OF SERVICE |

| A. V. Kastner | 21000 | 1987 | 1987 | Sold in 2010 to Dubai, renamed Silica II |

| Gypsum Centennial | 32881 | 2001 | Renamed Algoma Centenial | |

| Gypsum Integrity | 33047 | 2009 | Renamed CSL Frontier |

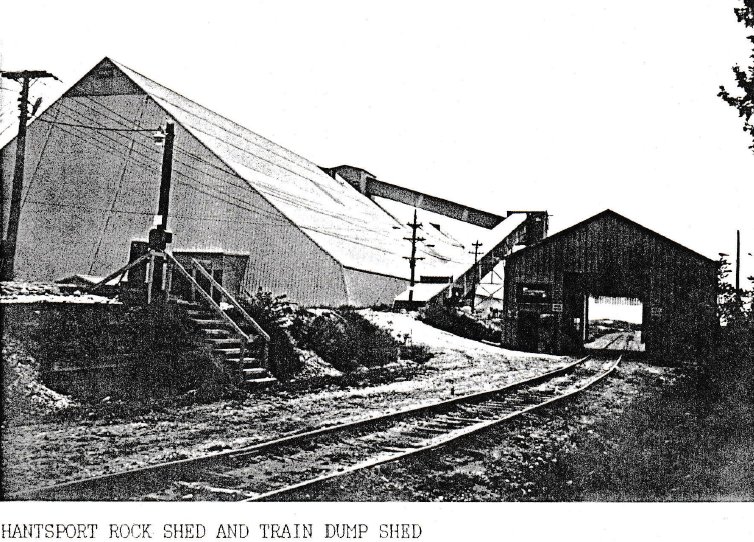

The first rock storage shed was built in 1909. This shed was one and one-quarter miles from the Wentworth wharf and halfway to the main quarry, which at that time was the Meadow Quarry or the Eagle Swamp Quarry (Dimock’s Quarry). It was probably on the railroad to the latter as there were five fatalities in that quarry between 1873 and 1907, suggesting that the quarry was quite busy.

The shed was used for storing rock during the river’s ice conditions and it allowed production to continue during the winter.

As the demand for rock increased, the company wanted to start shipping in winter. Shand (1979) reported that a local paper mentioned that the first cargo was sent to Digby, an ice-free port, on January 10, 1917.

A 195,000 ton shed was built at Deep Brook, Digby County in 1927-28. This shed was ninety miles southwest of Wentworth by railroad and allowed continued winter shipping plus kept an emergency rock supply. The last shipment from Deep Brook was in 1956 and the facility was closed in 1957.

As a result of a reorganization of corporate structure, Canadian Gypsum Company Windsor plant became Fundy Gypsum Company Limited, a subsidiary of the United States Gypsum Company, on January 1, 1962.

Local Managers

| 1871 – 1892 | E.W. Dlmock; Died 1892 |

| 1892 – 1899 | Clarence and Norman Dimock |

| 1899 – | Norman Dimock; died 1933 Jim Blight John Robinson |

| Pre 1919 – 1929 | Otis Wack (later became Vice President in Chicago) |

| 1930 – 1935 | Wells Anderson |

| 1936 – 1948 | Sherred Willis |

| 1949 – 1981 | Mike King |

| 1982 – | Gerry Raymond |

With the loss of the company’s ships during World War II, studles were made to determine how the entire Nova Scotia operation could be improved and the capacity raised.

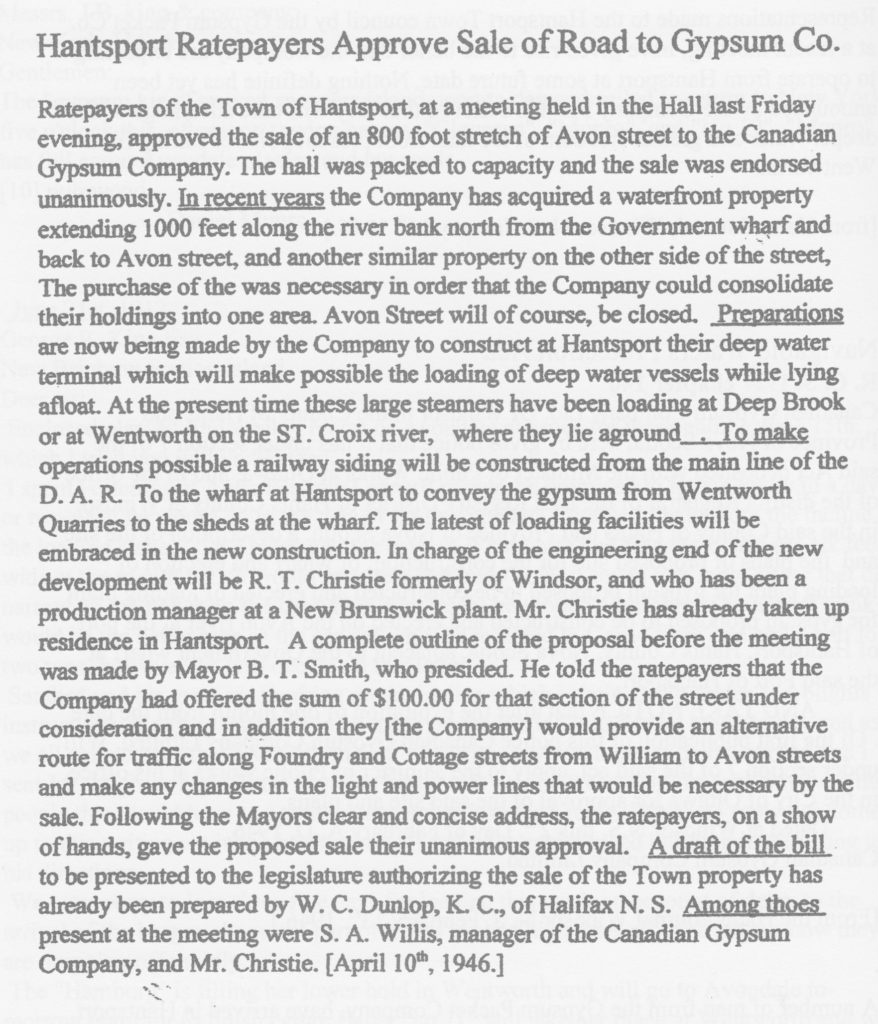

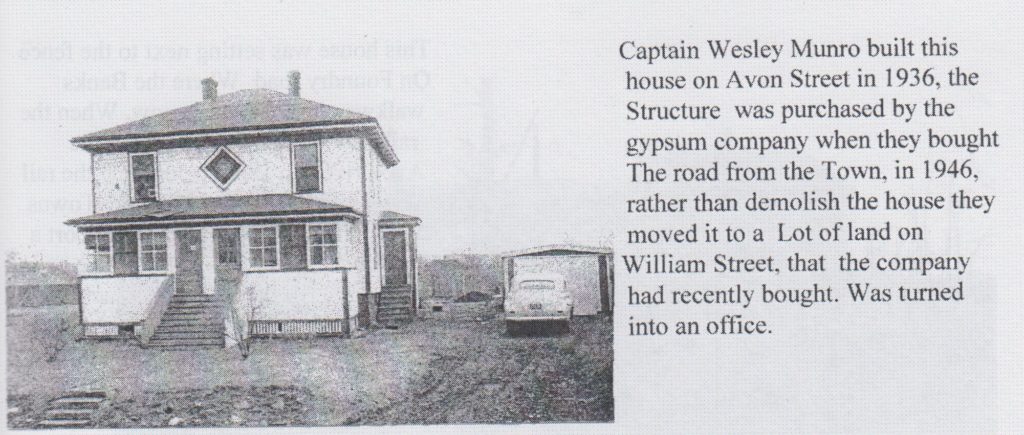

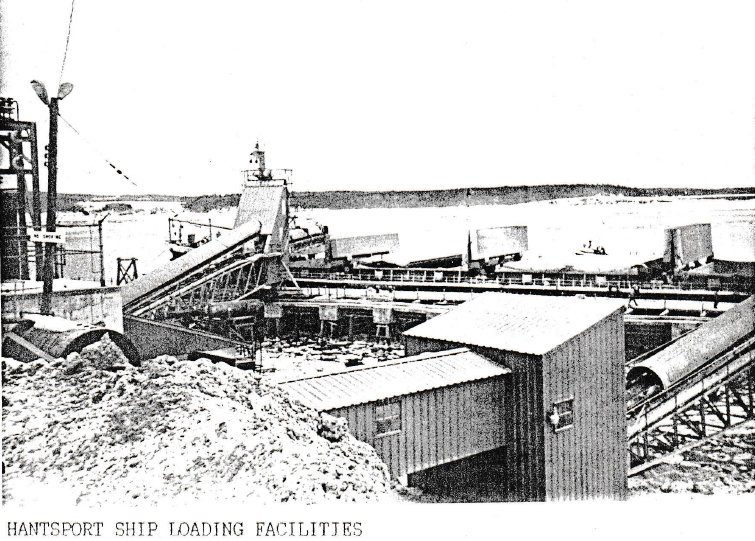

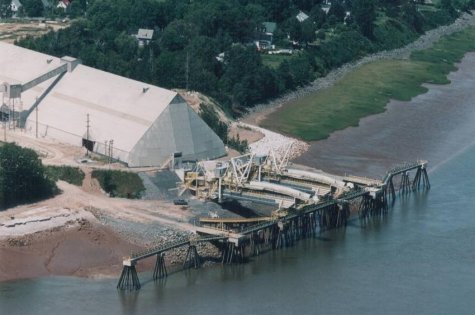

Construction was completed in 1947 on a 130,000 ton storage shed at Hantsport, which is eight miles northwest of Windsor on the Avon River. This location also has loading equipment and docks to accommodate deep draft vessels including the 21,000 ton self-unloading ships throughout the entire year. Because of the extreme height (40-50 feet) of the Minas Basin tides, ships must dock, load and sail within three hours to avoid getting stuck in the mud.

This facility, originally designed to load at a rate of 6,000 tons per hour, has been upgraded to load at a rate of 10,000 tons per hour to be able to fill the larger ships in time. This upgrade in 1976 increased the speed of the loading belts and the boom belt discharge chutes were redesigned.

The Gypsum Transportation Company Limited of Hamilton, Bermuda, took over the duties of shipping gypsum from the Gypsum Packet Company in 1961.

Rock from the white gypsum and anhydrite quarries at Wentworth and the dark gypsum primarily from Bailey and Miller’s Creek quarries are shipped by water to United States Gypsum Company plants at Boston, Stony Point, Baltimore, Norfolk, Jacksonville and New Orleans.

On September 12, 1974 after continuous white gypsum shipments from Wentworth to Staten Island extending back to the late 1800’s, the last cargo for the New Brighton plant was shipped on the Gypsum Queen.

The largest cargo (23,882 short tons) ever stowed at Hantsport [1990] was loaded on a charter ship in two hours and fifty minutes on May 25, 1987.

Rail Operations6

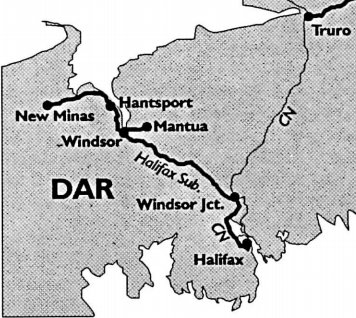

The DAR came into existence in 1894, when the Windsor and Annapolis Railway purchased the Yarmouth and Annapolis Railway, and renamed the combined line, from Windsor to Yarmouth, as the Dominion Atlantic. In 1905 , the DAR acquired the Midland Railway, which extended from Windsor to Truro . The DAR was leased to the CPR in 1912 for a period of 999 years. The Windsor Branch of the Intercolonial Railway, between Windsor and the connection with the ICR main line at Windsor Jct., was placed under the control of the W&A in 1871, and was leased by the DAR for 99 years beginning in 1914.

When the DAR was consolidated with the rest of CP’s track east of Megantic, Quebec, in 1988 to become the Canadian Atlantic Railway business unit, it consisted of the Yarmouth, Kentville, and Halifax subdivisions between Yarmouth and Windsor Jct., running rights over CN to get to Halifax, and the remaining 4.4 miles of the Truro Subdivision to Mantua.

All DAR track from Yarmouth to a point five miles west of Kentville was abandoned between 1989 and 1991. This left only the Halifax Subdivision from Windsor Jct. to Kentville and the Truro Spur from Windsor to Mantua. Effective on September 23, 1993, CP was permitted to abandon the Halifax Subdivision and all spurs west of Mile 52. 9 (at New Minas, 3.2 miles east of Kentville). The last train to operate to Kentville was on September 16, when SW1200RS 1275 returned with two cars and a van.

The locomotives and cabooses currently assigned [1993] to the DAR are SW1200RSs 1272 (used as a spare), 1274, 1275 , and 8138 , and vans 434676 and 434678. Operations used to be based at the CN Rockingham Yard, near Halifax, but since May 18, 1992 , have been based at Hantsport. From Hantsport, there are now up to four gypsum turns operating each day, Monday to Friday. An extra job on the weekend takes traffic to Windsor Jct. to interchange with CN, when required.

The first crew of the day, ordered for 06:00 (all DAR operations are on Eastern Time, not local Atlantic Time), takes empty cars from Hantsport to either the mine at Dimock’ s (Mile 2.3, Truro Spur) or the one at Mantua (Mile 4.4, Truro Spur). Loaded cars are then picked up at one of those two locations for the return trip to Hantsport. The loaded cars are placed in the yard at Hantsport, where the Fundy Gypsum switcher (a GE 45-ton switcher) lifts them, a few at a time, for unloading at the Fundy Gypsum pier for transfer onto a ship for the U.S . While the Fundy switcher is unloading cars, the CP crew lifts another train of empty cars and makes a return trip, either to Mantua or Dimock’s. The morning CP crew will make up to two runs, and an afternoon crew called for 16:00 will make up to another two runs. The morning crew is a regular assignment, but the afternoon crew is called from a freight pool based in Kentville. They report to the car shop building in Kentville, and then deadhead to Hantsport by car.

The first short-line railway to be spun-off from CP’s Canadian Atlantic Railway is scheduled to begin operations on January 31, 1994 , pending NTA approval[1993]. CP announced that it will sell its Nova Scotia track, once known as the Dominion Atlantic Railway, to a U.S. railway acquisition and management company.

Iron Road Railways Inc., based in Washington, D.C. , will purchase 60 miles of track from just east of Kentville to Windsor Jct. and from Windsor to Mantua, eight locomotives, and 76 cars . The new operation will be the Windsor and Hantsport Railway, in which there are a number of unnamed Maritime investors. CP put the track up for sale last November, and has been negotiating with Iron Road for the past five months. The line currently generates $3-million a year in revenue.

This acquisition is the first for Iron Road, whose principals have worked in the rail industry for CSX Transportation, Conrail , and CP Rail System. Bob Schmidt, Iron Road’ s chief executive officer, said he expects the Windsor and Hantsport’ s revenue to double within five to ten years through long-term contracts with key shippers. The company will encourage a non-union environment by paying employees incentives for reaching volume and cost-cutting targets. CP said incentives were provided to encourage the W&H to hire current CP employees . The W& H will employ 20 people and, in addition to the 76 cars purchased from CP, may seek an additional 60 cars for gypsum traffic. The locomotives that the W&H is expected to purchase from CP are RS23s 8026, 8027, 8036, 8037, 8038, 8041, 8042, and 8046 (8037 is one of three RS23s lettered for the Canadian Atlantic Railway). All of these units are currently assigned to Saint John .

Gypsum accounts for almost all of the shipments on the line now, and it is shipped a maximum distance of 10.1 miles from Mantua to Hantsport. The gypsum trains operate in 25-car lengths , and consist of 44-foot steel gondolas (GS type) with two drop-bottom doors. The cars are numbered CP 352924-352999, and the W&H will be purchasing all 76 cars. The cars are all still equipped with friction-bearing trucks.

New Wharf and Loading Facility 2003/4

A multi-million dollar upgrade was completed including a new wharf consisting of 10 pile supported dolphins, renovation to the storage shed and replacement of the ship loading conveyors.

End of an era – 20117

USG Corp (United States Gypsum ) and indirectly through CGC (Canadian Gypsum Co) announced that its Fundy Gypsum Co. operation is to be closed permanently. The quarries at Wentworth and Miller’s Creek and port facilities at Hantsport were once a mainstay to the local economy. The operation had been inactive for most of the year, due to the sluggish US construction industry, the destination for most of its product, and only a skeleton maintenance staff had been kept on, with no gypsum having been shipped in months.

It was a sad end to a unique operation which used an abundant local mineral (there is lots of gypsum left in the ground), but cheap imported wallboard and the US recession left the industry devastated. The mine and port were joined by a railroad, the Windsor & Hantsport, a short line that was once part of Canadian Pacific’s Dominion and Atlantic Railway (DAR). Fundy Gypsum was the line’s only customer recently and it has also been shut down.

The port of Hantsport, once a booming shipbuilding centre in the age of sail, is home to a huge warehouse and modern ship-loaders which have been idled since the last ship was loaded earlier in the year. The tug Spanish Mist which was owned by CGC, was sold in the spring to the Magdalen Islands.

Its most recent fleet upgrade saw two new self-unloaders, Gypsum Centennial built in 2001 and Gypsum Integrity built in 2009. They could carry 42,000 tonnes, and unload gypsum at a rate of 3,000 tonnes per hour. These ships have now found work in other bulk trades.

Hantsport posed an interesting challenge due to its tidal range in excess of 50 feet – the largest of any commercial port in the world. Ships had to arrive in port on a rising tide (the wharf dried out at low tide) and sail on the high tide or risk being stranded. Loading time was 3 1/2 to 4 hours, and the ship had to sail no matter how much cargo had been taken on. The new ship loaders could load in excess of 10,000 tonnes per hour each.

At its peak the port saw up to a dozen ships a month and exported 2 million tonnes of gypsum a year.

aboiteau and rail crossing

References:

- Nova Scotia Archives, A History of Mining Activity in Nova Scotia, 1720-1992,

- “Fundy Gypsum Company Limited, Windsor, Nova Scotia, Operating since 1924” by G. Raymond, January 1990.

- “White Rock: The Story of Gypsum in Hants County” by Edith Mosher, 1979.

- “United States Gypsum : a company history, 1902-1994” by Thomas W Foley; David Middleton Publisher: Chicago, Ill. : USG Corp., ©1995.

- “Gypsum Royal Fleet”, St. Clair H. Patterson, 2010.

- “The Last Days of the Dominion Atlantic Railway” by Gord Webster, Rail & Transit Number 527 – October 1993

- “USG pulls the plug”, November 2011, ShipFax

- “Province, railway company locked in legal battle over repairing crucial dike”, June 2018, CBC