The history of the Hantsport Foundry & Machine Works Company is tied to the life and career of Joseph Alexander Mumford, machinist and inventor. Born about 1847 at Woodville, age 32 at the time of his marriage in 1879 to Ella Dodge of Wilmot Springs, Annapolis County, he described his occupation then as “Millwright”. He was the son of Charles D. Munford (a house joiner or carpenter) and Elizabeth Woolaver, the family living in the Scotch Village, Hants County census division in 1871. Joseph then age 24 was described as a “Block Maker”.

Canadian and American patents awarded to Joseph Mumford include:

1877 Improvements in shingle machines

1886 Steam boiler

1887 Shingle sawing machine

1890 Steam engine

| 411,825 | Oct. 01, 1889 | J.A. Mumford | Shingle-sawing machine | shingle machines |

| 417,071 | Dec. 10, 1889 | J.A. Mumford | Barrel-head-sawing machine | barrel making machines |

| 431,704 | Jul. 08, 1890 | J.A. Mumford | Lubricator for steam-engines | steam engines |

| 558,698 | Apr. 21, 1896 | J.A. Mumford | Steam-boiler | stationary boilers |

| 598,292 | Feb. 01, 1898 | J.A. Mumford | Excavating or dredging bucket | |

| 616,580 | Dec. 27, 1898 | J.A. Mumford | Towing-machine |

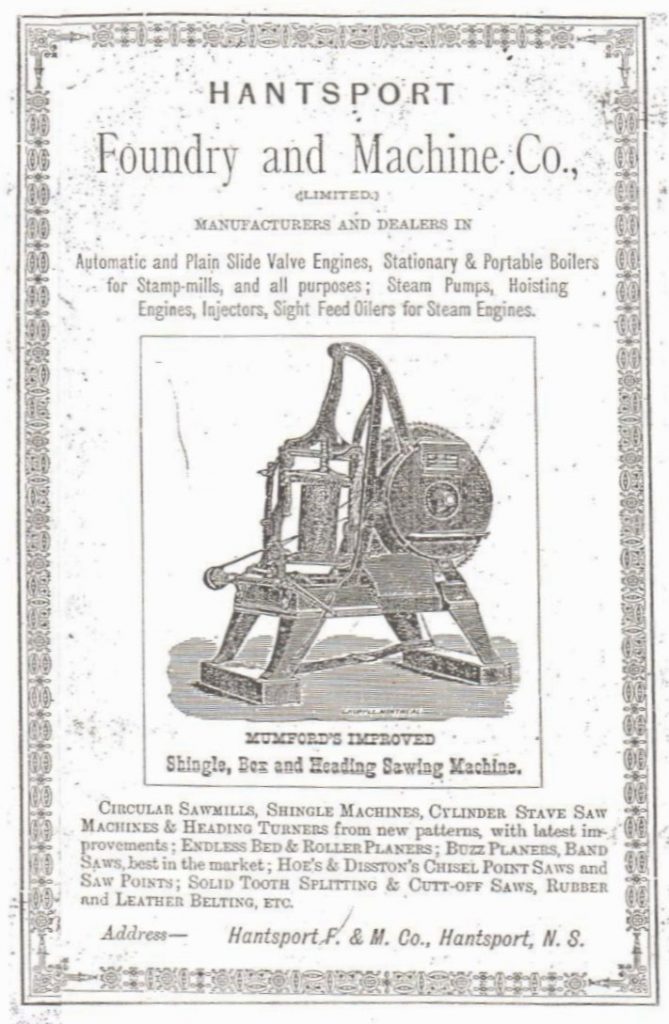

From the 1880s through to the 1890s, the Hantsport Foundry & Machine Company manufactured shingle-sawing machines. They also manufactured barrel-making machinery, and steam boilers.

The Foundry was incorporated and advertised in the Royal Gazette of 19 June 1889 with a proposed capital stock of $16,000, 400 shares at $25 per share.

The McAlpine Provincial Directory for 1890-1897 has four entries of interest:

Earl, Robert – pres’dt Hantsport Foundry & Machine Co.

Hantsport Foundry and Machine Company, Ltd., mfg. of Mill and General Machinery

Mumford, J. A., machinist, Hantsport

Parsons, B – sec. Hantsport Foundry & Machine Co.

There was unfortunately competition on many fronts and the company went bankrupt.

There is one final US patent application by Joseph Mumford on behalf of Robb Engineering Co., of Amherst, Nova Scotia.

| 1,003,776 | Sep. 19, 1911 | J.A. Mumford | Steam Boiler |

He was living in Nassau County, New York State with his only daughter, Harriette, at the time and died there on 28 March 1908 prior to the patent being awarded. There is a headstone for Joseph A. Mumford age 61 in Riverbank Cemetery, Hantsport.

Ford and Fordson Agricultural Show, Kent County, England, 2015

MUMFORD SHINGLE MILL

Manufactured by the Hantsport Foundry & Machine Co Ltd, Hantsport, Nova Scotia

This Mill was originally bought by Elmer Hart of Port Hawkesbury, Nova Scotia where he ran the mill for several years alongside another mill in his yard.

When these mills were first made they were being used to manufacturer boards for apple crates, not shingles but board. This changed when a board came off the saw as a shingle which changed the use and purpose of these machines.

The wood is cut to a thin taper, so that one end is paper thin and the other about one to two centimeters thick making them easier to layer on top of each other.

This type of Shingle Mill is a “Swinging Arm” type. The arm can be engaged and dis-engaged from the drive to load the logs / blocks of wood, which is mainly cedar.

Here the arm holding the log can bee seen “swinging” across the blade and cutting the log. After each cut the swinging arm returns to the start point and the log is angled over by one / two centimetre’s to form the taper of the shingle , as explained above. You can see the toothed cogged at top of & bottom of log, as well as having opposite direction movement of the coggs it also has off-set teeth, this is because it moves the log to angled then square, to angled then square for each new cut. This in turn give you the taper on the shingle. “It is so simple, but so clever” and manufactured so many years ago.